Introducción:

Los materiales plásticos se utilizan ampliamente en diversos campos, incluida la industria, la agricultura, la construcción, el embalaje y la fabricación de maquinaria. Debido a su peso ligero, bajo costo, resistencia a la corrosión y fácil procesamiento, los plásticos se han vuelto indispensables en muchas industrias. Sin embargo, durante el uso, los plásticos pueden sufrir envejecimiento debido a diversos factores, lo que puede afectar el rendimiento e incluso provocar fallas en el producto. Esto es especialmente crucial para las piezas de plástico en aplicaciones exteriores, como láminas posteriores fotovoltaicas y carcasas para equipos de telecomunicaciones, que están expuestas a entornos hostiles como la luz solar, la lluvia y las altas temperaturas. Si estos materiales carecen de suficientes propiedades antienvejecimiento, se degradarán prematuramente. Por lo tanto, es de gran importancia realizar pruebas de envejecimiento para evaluar la durabilidad de los materiales plásticos.

Yo. Principales objetivos de las pruebas de envejecimiento para materiales plásticos

El propósito de las pruebas de envejecimiento es evaluar la durabilidad y estabilidad de los materiales plásticos en diferentes condiciones ambientales, prediciendo así su vida útil y rendimiento en aplicaciones del mundo real. Al simular diversos factores ambientales, como temperatura, humedad, luz, oxígeno y medios específicos, se puede acelerar el proceso de envejecimiento de los materiales plásticos, lo que permite una evaluación integral de su resistencia al envejecimiento. La importancia de las pruebas de envejecimiento de materiales plásticos incluye:

- Evaluación de la estabilidad térmica: prueba de la estabilidad de los plásticos bajo temperaturas extremas para determinar su rendimiento a largo plazo bajo cargas continuas.

- Evaluación de cambios en las propiedades físicas: observación de deformación, fragilidad, agrietamiento y otros cambios en materiales plásticos durante ciclos de alta y baja temperatura.

- Determinación de la vida útil: simulación de entornos del mundo real para predecir la tasa de envejecimiento y la vida útil de los plásticos en aplicaciones reales.

- Optimización de productos compatibles: Proporcionar datos para la mejora de materiales y procesos de fabricación para ayudar a las empresas a mejorar la calidad del producto.

II. Características del envejecimiento, mecanismos y factores que influyen en los materiales plásticos

-

Características de envejecimiento de los plásticos:

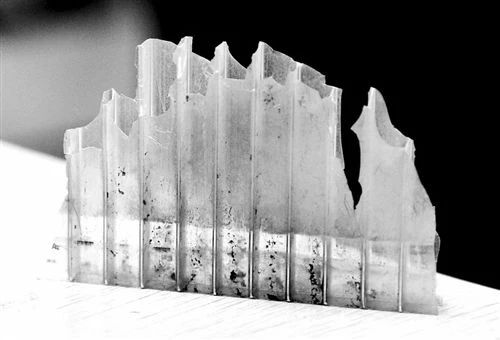

El envejecimiento de los plásticos se produce cuando factores ambientales a lo largo del tiempo, como el calor, la luz, la radiación de alta energía, el estrés mecánico, los ultrasonidos, los productos químicos y los microorganismos, provocan la degradación de sus componentes químicos. estructura, lo que lleva al deterioro de las propiedades físicas, químicas y mecánicas. El envejecimiento plástico se puede resumir en cuatro tipos de cambios: cambios de apariencia, cambios de propiedades físicas, cambios de propiedades mecánicas y cambios de propiedades eléctricas.

-

Mecanismos de envejecimiento plástico:

- Envejecimiento químico: Se trata de una reacción química irreversible resultante de cambios en la estructura molecular de los polímeros. Incluye fenómenos como la fragilización de los plásticos y el agrietamiento del caucho.

- Envejecimiento físico: Esto ocurre cuando factores externos hacen que el polímero vítreo pase de un estado de no equilibrio a un estado de equilibrio a través del movimiento browniano de pequeños segmentos de cadenas moleculares. Este proceso altera las propiedades físicas y mecánicas del material.

-

Factores que afectan el envejecimiento del plástico:

Los principales factores externos que influyen en el envejecimiento del plástico incluyen:- (1) Radiación, (2) Oxígeno, (3) Ozono, (4) Calor, (5) Humedad, (6) Estrés mecánico y (7) Otros.

- (1) Radiación, (2) Oxígeno, (3) Ozono, (4) Calor, (5) Humedad, (6) Estrés mecánico y (7) Otros.

III. Principios básicos y métodos de evaluación de pruebas de envejecimiento de materiales plásticos

-

Métodos de prueba de exposición natural:

Las pruebas de envejecimiento atmosférico natural estudian el envejecimiento de los plásticos en condiciones climáticas naturales. Este método implica exponer muestras a factores ambientales exteriores, donde sufren una combinación de efectos climáticos. Midiendo los cambios en las propiedades antes y después de la exposición, se puede evaluar la resistencia al envejecimiento del material.- Envejecimiento natural en almacenamiento: Realizada en salas de almacenamiento o almacenes bajo condiciones climáticas naturales o condiciones simuladas del mundo real, esta prueba evalúa la resistencia al envejecimiento de los materiales en función de los cambios de propiedad antes y después de la exposición.

- Prueba de exposición marina: las muestras se exponen a diferentes entornos marinos y su resistencia al envejecimiento se evalúa midiendo los cambios en las propiedades antes y después de la exposición.

Las pruebas de envejecimiento natural simulan fielmente las condiciones de trabajo reales y utilizan equipos simples. Sin embargo, requieren grandes instalaciones, tiempos de prueba prolongados y están sujetos a cambios climáticos, lo que dificulta la obtención de resultados cuantificables. Los resultados son aplicables a sitios de prueba de exposición específicos.

-

Pruebas de envejecimiento artificial:

Las pruebas de envejecimiento artificial se realizan en laboratorios e incluyen los siguientes métodos:- Prueba de envejecimiento térmico: Esta prueba evalúa la resistencia del material a altas temperaturas. Las muestras se colocan a temperaturas superiores a sus condiciones operativas habituales y se miden los cambios en las propiedades antes y después de la exposición para evaluar la resistencia al calor.

- Prueba de envejecimiento por exposición a calor y humedad: esta prueba expone materiales a aire caliente y húmedo para evaluar la resistencia a ambientes cálidos y húmedos en función de los cambios de propiedad o apariencia antes y después de la exposición.

- Prueba de envejecimiento térmico de aire y oxígeno a alta presión: Realizada en condiciones de alta temperatura y alta presión, esta prueba evalúa la resistencia a la intemperie en función de los cambios de propiedad o apariencia antes y después de la exposición.

- Prueba de intemperismo artificial: las muestras se exponen a condiciones ambientales simuladas, como luz, calor, oxígeno, humedad y lluvia, para evaluar la resistencia a la intemperie en función de los cambios en la irradiancia o radiación en la superficie de la muestra.

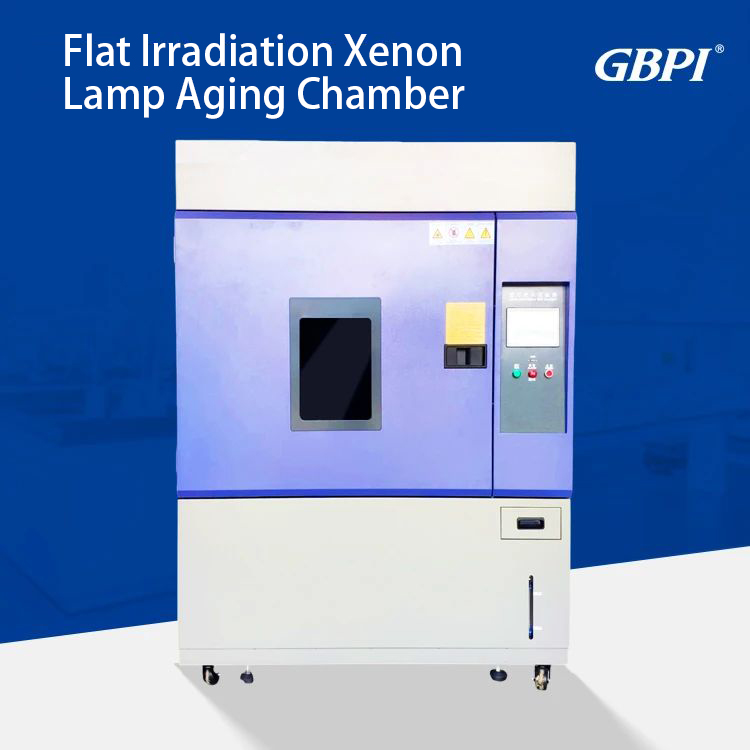

La imagen muestra la cámara de envejecimiento acelerado de alta presión (saturada) y la cámara de envejecimiento de la lámpara de xenón de panel plano de Guangzhou Biaoji, que son populares por su estabilidad y alta precisión de prueba.

-

Método de tasa de flujo de fusión (MFR):

El método MFR mide el índice de flujo de fusión de materiales después del envejecimiento bajo condiciones de carga y temperatura específicas en un instrumento de índice de flujo de fusión. La tasa de flujo de fusión disminuye a medida que aumenta el tiempo de envejecimiento, y esta tasa se cuantifica para evaluar el envejecimiento. Las pruebas de envejecimiento artificial son ventajosas por su corto ciclo de prueba, su independencia del campo y el clima y su alta repetibilidad. Sin embargo, requieren equipos de prueba sofisticados y se usan comúnmente para la detección del envejecimiento.

info@gbtest.cn

info@gbtest.cn

es

es en

en ru

ru ar

ar